Continuous monitoring of chemicals in the pharmaceutical industryÂ

Ana Gonzalez and Jose Pozo of the European Photonics Industry Consortium (EPIC) highlight pilot-line opportunities for companies looking to introduce novel Mid-IR sensors in the market.

Chemicals are widely employed across a range of industrial sectors allowing the manufacturing of many of the products that we use daily. From an apple to a car, chemicals can be employed at multiple points the production supply chain. However, their uncontrolled use can risk serious contamination of the environment, food production chain, and healthcare services.

For this reason, the pharmaceutical industry is heavily controlled to ensure the composition of drugs administered to patients. Related chemical processes require strict quality checks to assess the purity, reproducibility, homogeneity, and warn of the presence of contaminants, among other factors. Current evaluation techniques include sampling, transportation to a specialized laboratory, purification of the sample (which is done by skilled personnel), and the final detection using bulky and expensive equipment. Since these actions are time-consuming and costly, and usually the sample is destroyed during the analysis, only a small fraction of the final drug can be analysed. In addition, these analytical tools are bulky and requires optimization and calibration steps, which creates a hurdle for in-line monitoring.

Batch versus continuous manufacturing

In many cases, batch pharmaceutical manufacturing (where all the materials are charged before the start of processing and discharged at the end of processing) is now replaced by cleaner, flexible and more efficient continuous manufacturing, which can avoid off-line delays. In a continuous manufacturing process, material is simultaneously charged and discharged from the process.

Continuous manufacturing has some advantages when comparing with batch manufacturing such as no manual handling is required, increased safety, shorter processing times, more flexible operation and smaller ecological footprint. However, how to warranty that the product has a uniform content and quality within specified limits? Clearly, the answer is related to the implementation of in-line monitoring detection tools in the manufacturing process.

Mid-IR platform

Mid-Infrared (Mid-IR) technology is based on the strong interaction of light with molecular vibrations. Spectroscopic sensing in the Mid-IR wavelength band (3-12 µm) is a powerful analytical tool since the chemicals exhibit their fingerprint region, intense adsorptions that allow unambiguous identifications and quantifications of molecules.

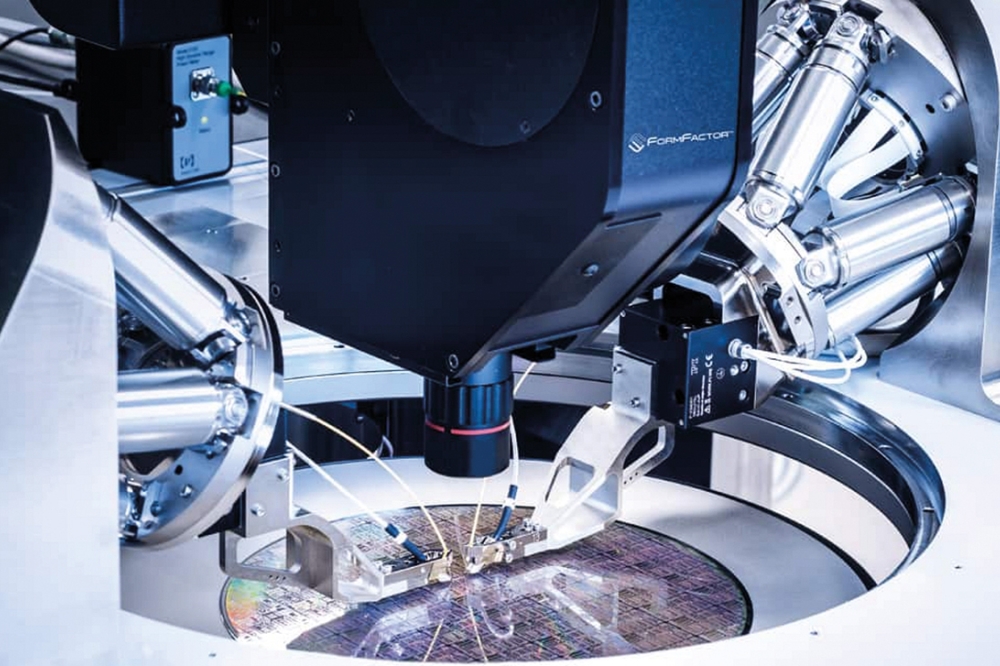

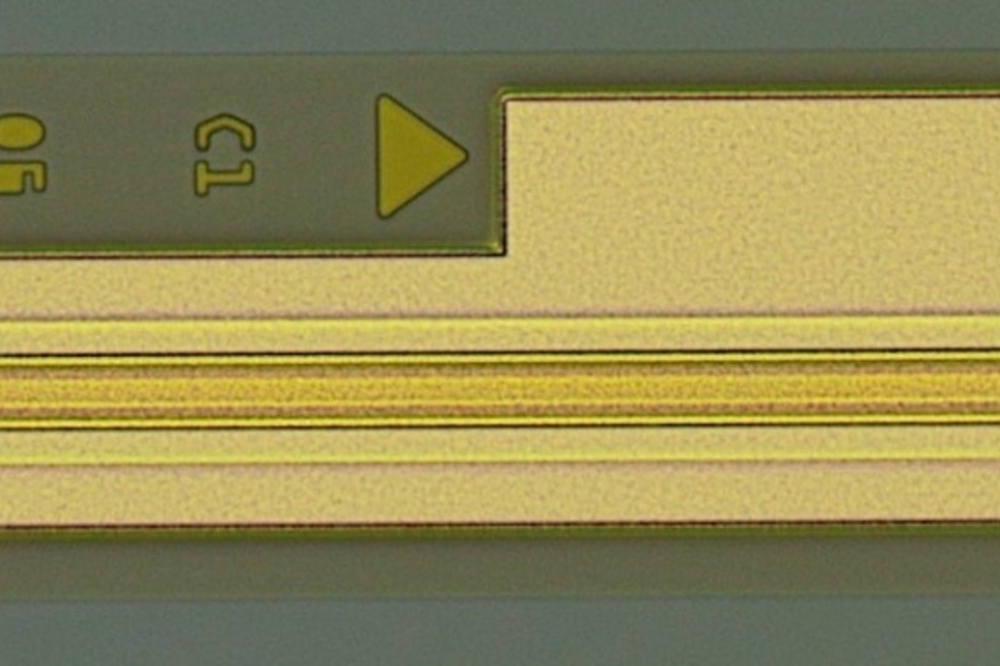

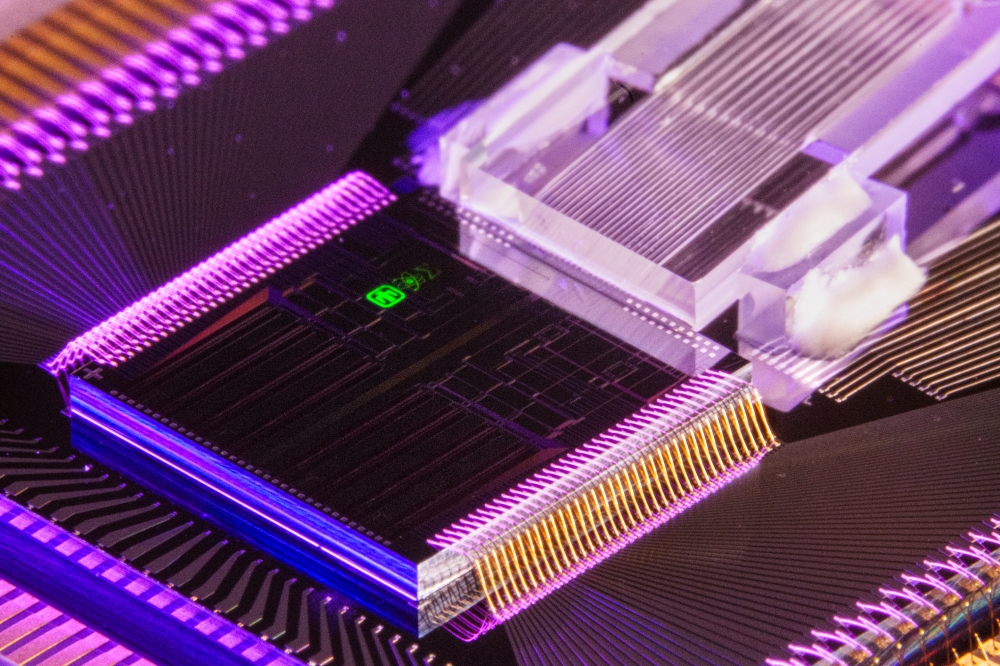

A Mid-IR sensor consists of: i) a laser source, usually Interband Cascade Lasers (ICLs) and Quantum Cascade Lasers (QCL), ii) the passive components (PICs) or free-optics, and iii) a detector (type-II InAs/GaSb superlattice (T2SL), InAsSb and Quantum Cascade Detectors (QCD)). Packaging of the final devices includes the integration of the photonics components and the electronics on the same platform which reduce the size of the sensing system (see image below). Other advantages are a high sensitivity and selectivity, which allows unattended, direct and fast detection of the sample without the requirement of any pretreatment - fundamental requisites to integrate these devices into manufacturing lines.

Photodetectors integrated with electronics.

The increasing attention of the scientific community to Mid-IR sensing has driven several studies demonstrating the enormous potential of the Mid-IR technology (see Ref [1] as an example). Regarding new devices for quality control in pharma, it is helpful to highlight the work recently presented by Li et al. in which they develop a Mid-IR imaging system enabling mapping both active pharmaceutical ingredients and excipients of a drug tablet [2].

MIRPHAB "“ pilot production of Mid-IR sensors

Since the demand for continuous monitoring of chemical production is getting bigger, high growth for spectrometer sensor systems could be expected in future years. A 2016 report indicated that the total market of compact spectrometers will increase from $157M in 2015 to $297M in 2021 [3]. New applications will be fulfilled by using these technologies, and novel devices must be designed and tested, which will require the involvement of new manufacturing players.

The objective of MIRPHAB Pilot Line (Mid-Infrared Photonics Devices Fabrication for Chemical Sensing and Spectroscopic Applications) is to help these new actors in the field of Mid-IR chemical sensing. MIRPHAB is a unique opportunity for small-medium companies that want to introduce novel Mid-IR sensors in the market. MIRPHAB offers a single-access point to the best Mid-IR facilities and expertise in Europe allowing the production of prototypes, and assuring the supply of components for the next generation of chemical sensors based on Mid-IR technologies.